Ad Code

Translate

List of 6,000+ Dofollow Commentluv Blogs FREE (Updated 2025)

What is Ozempic (semaglutide)? (Updated in 2025)

How To Find Suitable Properties In Cyprus? (Updated in 2025)

Smart strategies for trading on crypto exchanges

Applications for Universal Robot Cobots

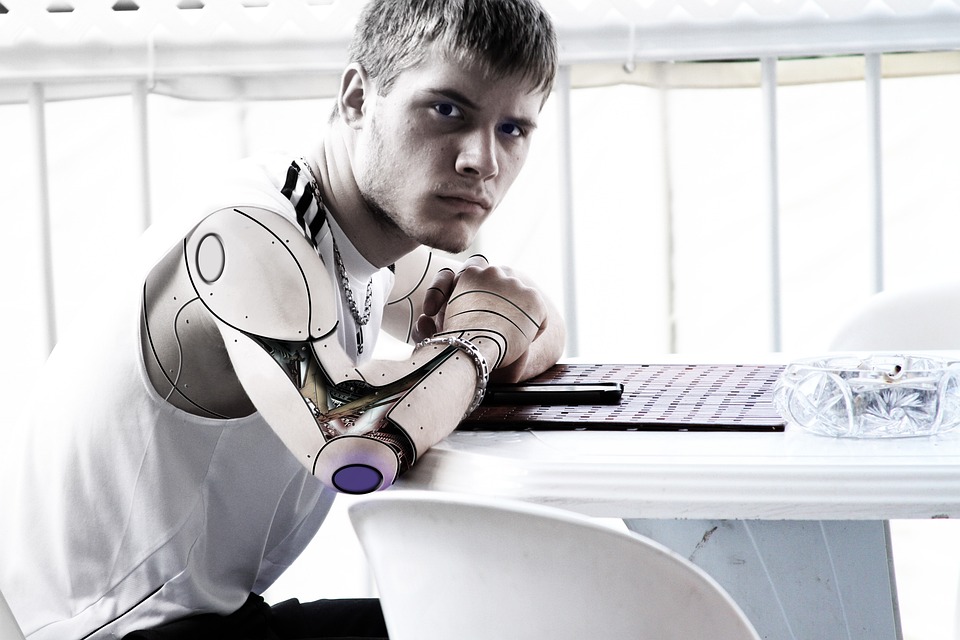

Cobots

or Collaborative Robots have been showing up in the robotic market since 2017,

and the collaborative robot market is only expected to keep growing,

considering that many industries are looking to introduce cobots.

Robots

have replaced human labour in critical and risky factory jobs to operate within

safety measures. Since the industrial revolution, robots have taken away some

of the spatial and environmental dangers that traditional robots tend to cause.

Cobots can there successfully work alongside humans in a factory.

Compared

to traditional robots, cobots have a more natural interaction with humans. They

can comfortably share the same workspace as factory employees, and they can be

easily reprogrammed.

Common Applications for Cobots

Picking and Placing

Pick

and place robots are designed to identify objects or parts in a factory and

package them accordingly. Before cobots, human workers would do repetitive pick

and place tasks all by themselves. Because of how mundane this task can get;

workers are prone to make mistakes. They are also prone to strain or injury due

to repetitive physical motions.

Pick

and place robots are best suited for first-time collaborative robot users. All

the robot has to do is pick a workpiece and place it in a different location. This could be packaging or sorting functions from a conveyor belt system and tray; however, the latter needs advanced vision systems.

Packaging and Palletizing

This

is another subset of pick and place where products are packaged and palletized.

Before products can leave the factory floor, they need proper preparation for

shipment. This includes; box assembling and loading, shrink-wrapping, and box

collating and placing on a pallet for shipment.

These

tasks are ideal for cobots because they involve small payloads, and they are

repetitive. Businesses running high or low mixes of volume production require

rapid product changeover.

For this application to successfully

synchronize robotic movement with a conveyer, conveyor tracking is required.

Products with non-uniform shapes may also need a vision system.

Machine Tending

Machine

tending in factories requires a worker to stand in front of a CNC or injection-modelling

machine, or any other similar device for many hours and keep tending to the

machines' operational needs. The worker could need to change the tools or

replace raw materials. For a human operator, this is a long and tiring process.

Cobots

will free human operators because a single cobot can tend to many machines.

This will also increase productivity in the factory. However, these cobot

applications need the robot to have input and output interfacing hardware

where you can indicate what the robot's next cycle is or when the materials

might need replenishing.

Processing Tasks

Universal robots are one of the

few robots that feature a specially designed welding end-effector. Some cobots

have different end-effectors like glue dispensers for various process tasks.

Process tasks need tools to interact with workpieces like dispensing,

processing, glueing, or welding.

These

process tasks need a tool to go down an already fixed path over and over.

Hence, they take a lot of time to train new workers to achieve the required

finish. Programming can be finished on one unit and copied to another.

Hence

with cobots, human workers don't have to perform precise and repetitive movements.

Cobots will ease programming through place and position records allowing

workers with welding experience to program them easily.

Cobots

also feature a polyscope interface that helps maintain constant TCP speed. This

ensures that the cobot deposits material at a steady rate. In these cases, the

end effectors are unique because they need to hold a sealant, solder paste,

welding torch, or glue.

In Conclusion

In

the future, cobots will play more significant roles in the upcoming industrial

revolution. The only disadvantage is that many unskilled labour jobs can be

rendered useless overnight by cobots. Luckily, new jobs will still open because

even cobots need occasional maintenance.

0 Comments